How reliant is your business on battery power? Whether you’re in the automotive, industrial or manufacturing game or your enterprise simply couldn’t keep its wheels turning without tools and equipment that require the smooth operations of one of the world’s handiest and most widely used methods of providing unplugged power, batteries are nigh-on indispensable these days.

So are you taking your everyday reliance on batteries seriously enough?

We’re not just talking about the downtime and lost productivity when they go flat or they go wrong. Staying up to date with your battery testing equipment means keeping tabs on operational benchmarks, saving time and money with proper maintenance and servicing as part of your normal operations, cutting out injuries and minimising hazards by spotting faults before they happen, and boosting your efficiency and empowering your decision-making with a full understanding of every detail that makes your business tick.

Convinced that you need to update your battery testers? Good move.

The next step is to match your needs with the correct battery tester by understanding what type you need, which features it should possess, and assessing the budget you’re setting aside for this crucial area of operations.

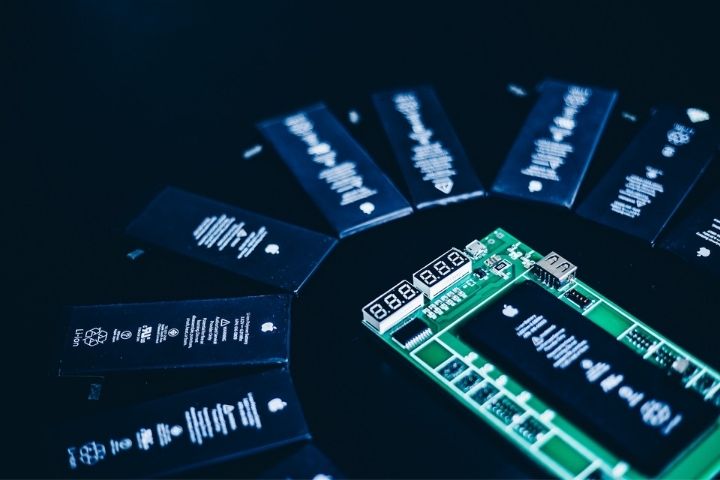

But first, let’s take a deeper look at the indispensable technology category of battery testing equipment, and understand how the magic happens. To boil it down to the most basic explanation, a battery tester will let you know if your battery is putting out the promised voltage, giving you the heads-up about failures or when it just needs a charge.

More sophisticated versions will delve deeper into energy capacity at various charging or discharging rates, the internal resistance or impedance, and the cycle life, battery robustness, heat generation – and more.

At the most basic level, though, a battery tester can be as simple as the conductive ink versions that some battery packaging includes. When a battery is charged, the high levels of current will heat up the ink to show a higher level of charge, with lower current levels not getting the ink as hot and therefore indicating lower charge via the measurement reference.

The next level of battery tester technology is the basic analogue device featuring a needle gauge. This is how it works:

Table of Contents

Complete The Circuit

When any battery tester is properly connected to a battery, you’re letting the electricity flow into the tester by completing a circuit.

Electromagnetic Waves

This flow of voltage and current creates electromagnetic waves. The more voltage and current that is present will result in a greater number of these electromagnetic waves being generated.

Wire Coil

While the latest and most accurate and feature-rich battery testers of today are digital, at the centre of the workings of an analogue tester is a wire coil that is suspended between magnets. The electromagnetic waves originate at the coil and, depending on the amount of waves, the needle indicating to the user the level of charge will correspondingly pivot.

The final word: Make Battery Testing Part Of Your Everyday Operations

And finally, because digital testers work by analysing the battery’s internal resistance, it means even discharged batteries can be tested with the latest testing technology, while amp probes allow for highly accurate and complex diagnostics far beyond a simple analogue current measurement.

But in the end, it’s not an understanding of the inner workings of your battery tester that will provide the efficiency, productivity and cost reduction benefits. Rather, it’s the smooth incorporation of effective and consistent testing regimes that will make your business better, faster, more technology-proof – and more profitable.